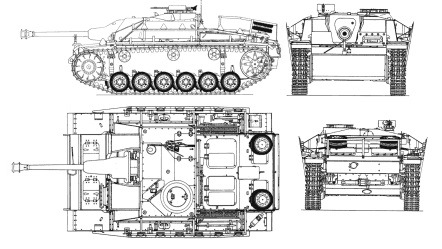

| Sturmgeschutz III. |

|---|

|

|---|

| Sturmgeschutz III. |

|---|

|

|---|

| Sturmgeschutz III With Side Panel. |

|---|

| Type: | Assault Gun. |

|---|

| Place Of Origin: | Nazi Germany. |

|---|

| Service History: |

|---|

| In Service: | Germany: 1940-1945;Syrian: 1967 (Six-Day War);Possibly later. |

|---|

| Used By: | See Operators. |

|---|

| Wars: | World War II (Continuation War);Six-Day War. |

|---|

| Production History: |

|---|

| Unit Cost: | 82,500 RM. |

|---|

| Number Built: | ≈10,086 StuG III;≈1,299 StuH 42. |

|---|

| Specifications: |

|---|

| Weight: | 23.9 tons (52,690 lbs). |

|---|

| Length: | 6.85 m (22 ft 6 in). |

|---|

| Width: | 2.95 m (9 ft 8 in). |

|---|

| Height: | 2.16 m (7 ft 1 in). |

|---|

| Crew: | 4. |

|---|

| Armor: | 16 - 80mm (.62 - 3.15 in). |

|---|

| Main Armament: | 1 times 7.5CM StuK 40 L/48, 54 rounds. |

|---|

| Secondary Armament: | 1 times 7.92MM MG34 machine gun, 600 rounds. |

|---|

| Engine: | Maybach HL 120 TRM V-12 gasoline engine driving six-speed transmission, 300 PS (296 hp, 221 kW). |

|---|

| Power/Weight: | 12.6 PS/ton. |

|---|

| Suspension: | Torsion bar. |

|---|

| Operational Range: | 155 km (96 mi) (.9 mpg-US (1.1 mpg-imp; 260 L/100 km) at 22 mph (35 km/h), 71 US gal (59 imp gal; 270 l) fuel). |

|---|

| Speed: | 40 km/h (25 mph). |

|---|

|

|---|

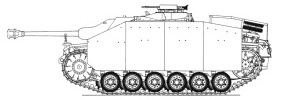

| Sturmgeschutz III In Action In Chinese Livery. |

|---|

The Sturmgeschutz III (StuG III) assault gun was Germany's most produced armored fighting vehicle during World War II. It was built on the chassis of the proven Panzer III tank, replacing the turret with a fixed casemate and mounting a more powerful gun. Initially intended as a mobile, armored light gun for direct-fire support for infantry, the StuG III was continually modified, and much like the later Jagdpanzer casemate-styled specialist armored vehicles, was widely employed as a tank destroyer.DevelopmentThe Sturmgeschutz III originated from German experiences in World War I when it was discovered that, during the offensives on the western front, the infantry lacked the means to effectively engage fortifications. The artillery of the time was heavy and not mobile enough to keep up with the advancing infantry to destroy bunkers, pillboxes, and other minor obstacles with direct fire. Although the problem was well known in the German army, it was General Erich von MANSTEIN who is considered the father of the Sturmartillerie ("assault artillery"). This is because the initial proposal was from (then) Colonel Erich von MANSTEIN and submitted to General Ludwig BECK in 1935, suggesting that Sturmartillerie units should be used in a direct-fire support role for infantry divisions. On June 15, 1936, Daimler-Benz AG received an order to develop an armored infantry support vehicle capable of mounting a 75MM (2.95 in) caliber artillery piece. The gun mount's fixed, fully integrated casemate superstructure was to allow a limited traverse of a minimum of 25 degrees and provide overhead protection for the crew. The height of the vehicle was not to exceed that of the average soldier.Daimler-Benz AG used the chassis and running gear of its recently designed Panzer III medium tank as a basis for the new vehicle. Prototype manufacture was passed over to Alkett, which produced five prototypes in 1937 on Panzer III Ausf. B chassis. These prototypes featured a mild steel superstructure and Krupp's short-barreled, howitzer-like in appearance, 75MM StuK 37 L/24 cannon. Production vehicles with this gun were known as StuG III AusfUhrung (version) A to E.While the StuG III was considered self-propelled artillery, it was not initially clear which land combat arm of the Wehrmacht Heer would handle the new weapon. The Panzer arm, the natural user of tracked fighting vehicles, had no resources to spare for the formation of StuG units, and neither did the infantry branch. It was agreed, after a discussion, it would best be employed as part of the artillery arm.The StuGs were organized into battalions (later renamed "brigades" for disinformation purposes) and followed their own specific doctrine. Infantry support using direct-fire was its intended role. Later there was also a strong emphasis on destroying enemy armor whenever encountered.As the StuG III was designed to fill an infantry close support combat role, early models were fitted with a low-velocity 75

MM StuK 37 L/24 gun to destroy soft-skin targets and fortifications. After the Germans encountered the Soviet KV-1 and T-34 tanks, the StuG III was First equipped with a high-velocity 75MM StuK 40 L/43 main gun (Spring 1942) and in Autumn 1942 with the slightly longer 75MM StuK 40 L/48 gun. These versions were known as the Sturmgeschutz 40 AusfUhrung F, Ausf. F/8 and Ausf. G.When the StuG IV entered production in late 1943 and early 1944, the "III" was added to the name to separate it from the Panzer IV-based assault guns. All previous and following models were thereafter known as Sturmgeschutz III.Beginning with the StuG III Ausf. G from December 1942, a 7.92MM MG34 machine gun could be mounted on a shield on top of the superstructure for added anti-infantry protection. Some of the F/8 models were retrofitted with a shield as well. Many of the later StuG III Ausf. G models were equipped with an additional coaxial 7.92MM MG34.The vehicles of the Sturmgeschutz series were cheaper and faster to build than contemporary German tanks; At 82,500 RM, a StuG III Ausf G was cheaper than a Panzer III Ausf. M, which cost 103,163 RM. This was due to the omission of the turret, which greatly simplified manufacture and allowed the chassis to carry a larger gun than it could otherwise. By the end of the War, ≈11,300 StuG IIIs and StuH 42s had been built.Operational HistoryOverall, the Sturmgeschutz series assault guns proved very successful and served on all fronts as assault guns and tank destroyers. Although Tigers and Panthers have earned a greater notoriety, assault guns collectively destroyed more tanks. Because of their low silhouette, StuG IIIs were easy to camouflage and a difficult target. Sturmgeschutz crews were considered to be the elite of the artillery units and claimed to have knocked out 20,000 tanks by 1944. As of April 10, 1945, there were 1,053 StuG IIIs and 277 StuH 42s in service.The StuG assault guns were cost-effective compared to the heavier German tanks, though in the anti-tank role they were best used defensively, as the lack of a traversable turret was a severe disadvantage in the assault role. As the German military situation deteriorated later in the War, more StuG guns were built compared to tanks, to replace losses and bolster defenses against the encroaching Allied forces.In 1943 and 1944, the Finnish Army received 59 StuG III Ausf. Gs from Germany and used them against the Soviet Union. Thirty of the vehicles were received in 1943 and twenty nine in 1944. The 1943 batch destroyed at least 87 enemy tanks for a loss of only 8 StuGs (some of which were destroyed by their crews to avoid capture). The 1944 batch saw no real action. After the War, the StuGs were the main combat vehicles of the Finnish Army until the early 1960's. These StuGs gained the nickname "Sturmi," which can be found in some plastic kit models.100 StuG III Ausf. G were delivered to Romania in the autumn of 1943. They were officially known as TAs (or TAs T3 to avoid confusion with TAs T4) in the army inventory. By February 1945, 13 units were still in use with the 2ᴺᴰ Armored Regiment. None of this initial batch survived the end of the War. 31 TAs were on the army inventory in November 1947. Most of them were probably StuG III Ausf. G and a small number of Panzer IV/70 (V), known as TAs T4. These TAs were supplied by the Red Army or were damaged units repaired by the Romanian Army. All German equipment was scrapped in 1954 due to the Army's decision to use only Soviet armor.StuG IIIs were also exported to other nations, such as Bulgaria, Hungary, Italy, and Spain.Many German StuG IIIs were captured in Yugoslavia by Yugoslav partisans. These were used by the Yugoslav People's Army until the 1950's.After the Second World War, the Soviet Union donated some of their captured German vehicles to Syria, which continued to use them along with other War surplus armored fighting vehicles (like long-barreled Panzer IVs and T-34-85s) during the 1950's and up until the War over Water against Israel in the mid-1960's. By the time of the Six Days War, all of them had been either destroyed, stripped for spare parts, or interred on the Golan Heights as static pillboxes.VariantsProduction Numbers From Panzer Tracts 23- StuG III prototypes (1937, 5 produced on Panzer III Ausf. B chassis): By December 1937, two vehicles were in service with Panzer Regiment 1 in Erfurt. Vehicles had eight road wheels per side with 360-millimeter (14 in) wide tracks, 14.5mm thick soft steel superstructure and the 7.5CM StuK 37 L/24 gun. Although not suitable for combat, they were used for training purposes as late as 1941.

- StuG III Ausf. A (Sd.Kfz. 142; January 1940-May 1940, 30+6 produced by Daimler-Benz): First used in the Battle of France, the StuG III Ausf. A used a modified 5./ZW chassis (Panzer III Ausf. F) with front armor strengthened to 50mm. The last six vehicles were built on chassis diverted from Panzer III Ausf. G production.

- StuG III Ausf. B: (Sd.Kfz 142; June 1940-May 1941, 300 produced by Alkett) Widened tracks (380mm). Two Rubber tires on each road wheel were accordingly widened from 520 times 79mm to 520 times 95mm each. Both types of road wheels were interchangeable. The troublesome 10-speed transmission was changed to a 6-speed one. The forward most return rollers were re-positioned further forward, reducing the vertical movements of the tracks before they were fed to the forward drive sprocket, and so reduced the chance of tracks being thrown. In the middle of production of the Ausf. B model, the original drive sprocket with eight round holes was changed to a new cast drive sprocket with six pie slice-shaped slots. This new drive wheel could take either 380mm tracks or 400mm wide tracks. 380mm tracks were not exclusive to new drive wheels. Vehicle number 90111 shows older drive wheel with wider 380mm tracks.

- StuG III Ausf. C: (Sd.Kfz 142; April 1941, 50 produced) Gunner's forward view port above driver's visor was a shot trap and thus eliminated; instead, superstructure top was given an opening for gunner's periscope. Idler wheel was redesigned.

- StuG III Ausf. D: (Sd.Kfz 142; May-September 1941, 150 produced) Simply a contract extension on Ausf. C. On-board intercom installed, otherwise identical to Ausf. C.

- StuG III Ausf. E: (Sd.Kfz 142; September 1941-February 1942, 284 produced) Superstructure sides added extended rectangular armored boxes for radio equipment. Increased space allowed room for six additional rounds of ammunition for the main gun (giving a maximum of 50) plus a machine gun. One MG 34 and seven drum-type magazines were carried in the right rear side of the fighting compartment to protect the vehicle from enemy infantry. Vehicle commanders were officially provided with SF14Z stereoscopic scissor periscopes. Stereoscopic scissor type periscopes for artillery spotters may have been used by vehicle commanders from the start.

- StuG III Ausf. F: (Sd.Kfz 142/1; March-September 1942, 366 produced) The First real up-gunning of the StuG, this version uses the longer 7.5CM StuK 40 L/43 gun. Firing armor-piercing Panzergranat-Patrone 39, StuK 40 L/43 could penetrate 91mm of armor inclined 30 degrees from vertical at 500m, 82mm at 1,000m, 72mm at 1,500m, 63mm at 2,000m, allowing Ausf. F to engage most Soviet armored vehicles at normal combat ranges. This change marked the StuG as being more of a tank destroyer than an infantry support vehicle. An exhaust fan was added to the rooftop to excavate fumes from spent shells, to enable the firing of continuous shots. Additional 30mm armor plates were welded to the 50mm frontal armor from June 1942, making the frontal armor 80mm thick. From June 1942, Ausf. F were mounted with approximately 13 inch (334mm to be exact) longer 7.5CM StuK 40 L/48 gun. Firing above mentioned ammunition, longer L/48 could penetrate 96mm, 85mm, 74mm, 64mm respectively (30 degrees from vertical).

- StuG III Ausf. F/8: (Sd.Kfz 142/1; September-December 1942, 250 produced) Introduction of an improved hull design similar to that used for the Panzer III Ausf. J/L with increased rear armor. This was 8ᵗʰ version of the Panzer III hull, thus the designation "F/8." This hull has towing hook holes extending from side walls. From October 1942, 30mm thick plates of additional armor were bolted on to speed up the production line. From F/8, the 7.5CM StuK 40 L/48 gun was standard until the very last of the Ausf. G. Due to the lack of double baffle muzzle brakes, a few L/48 guns mounted on F/8s were fitted with the single baffle ball type muzzle brake found in Panzer IV Ausf. F2/G.

- StuG III Ausf. G (Sd.Kfz. 142/1; December 1942- April 1945, ≈8,423 produced, 142 built on Panzer III Ausf. M chassis, 173 converted from Panzer III): The final and by far the most common of the StuG series. Upper superstructure was widened: welded boxes on either sides were abandoned. This new superstructure design increased its height to 2,160mm. The back wall of the fighting compartment got straightened, and the ventilation fan on top of the superstructure was relocated to the back of the fighting compartment. From March 1943, the driver's periscope was abandoned. In February 1943, Alkett was joined by MIAG as a second manufacturer. From May 1943, side hull spaced armor plates (Schurzen) were fitted to G models for added armor protection, particularly against Russian anti-tank rifles, but were also useful against hollow-charge ammunition. Side plates were retro-fitted to some Ausf. F/8 models, as they were be fitted to all front line StuGs and other tanks by June 1943 in preparation for the battle of Kursk. Mountings for the side plates proved inadequately strong, as many were lost in the field. From March 1944, an improved mounting was introduced; as a result, side skirts are seen more often with late model Ausf G. From May 1943, 80mm thick plates were used for frontal armor instead of two plates of 50mm + 30mm. However, a backlog of StuGs with completed 50mm armor existed. For those, a 30mm additional armor plate still had to be welded or bolted on, until October 1943.

A rotating cupola with periscopes was added for the commander for Ausf G. However, from September 1943, the lack of ball bearings (resulting from USAAF bombing of Schweinfurt) forced cupolas to be welded on. Ball bearings were once again installed from August 1944. Shot deflectors for the cupolas were First installed from October 1943 from one factory, to be installed on all StuGs from February 1944. Some vehicles without shot deflectors carried several track pieces wired around the cupola for added protection.From December 1942, a square machine gun shield for the loader was installed, allowing an MG 34 to be factory installed on a StuG for the First time. F/8 models had machine gun shields retro-fitted from early 1943. The loader's machine gun shield was later replaced by rotating machine gun mount that could be operated by the loader inside the vehicle sighting through a periscope. In April 1944, 27 of them were being field tested on the Eastern front. Favorable reports led to installation of these "remote" machine gun mounts from the summer of 1944.From November 1943, G versions were fitted with the Topfblende pot mantlet (often called Saukopf "Pig's head") gun mantlet without a coaxial mount. This cast mantlet, which had an organic shape, was more effective at deflecting shots than the original boxy mantlet that had armor varying in thickness from 45mm to 50mm. The lack of large castings meant that the trapezoid-shape mantlet was also produced until the very end. A coaxial machine gun was First added to boxy mantlets, from June 1944, and then to cast Topfblende, from October 1944, in the middle of "Topfblende" mantlet production. With the addition of this coaxial machine gun, all StuGs carried two MG 34 machine guns from fall of 1944. Some previously completed StuGs with a boxy mantlet had a coaxial machine gun hole drilled to retrofit a coaxial machine gun; however, Topfblende produced from Nov. 1943 - Oct. 1944 without a machine gun opening could not be tampered with. Also from Nov.1943, all-metal return rollers of a few different types were used due to lack of rubber supply. Zimmerit anti-magnetic coating to protect vehicles from magnetic mines was used only from September 1943-September 1944.Further VariantsIn 1942, a variant of the StuG III Ausf. F was designed with a 105MM (4.1 in) howitzer instead of the 7.5CM StuK 40 L/43 cannon. These new vehicles, designated StuH 42 (Sturmhaubitze 42, Sd.Kfz 142/2), were designed to provide infantry support with the increased number of StuG III Ausf. F/8 and Ausf. Gs being used in the anti-tank role. The StuH 42 mounted a variant of the 10.5CM leFH 18 howitzer, modified to be electrically fired and fitted with a muzzle brake. Production models were built on StuG III Ausf. G chassis. The muzzle brake was often omitted due to the scarcity of resources later in the War. ≈1,299 StuH 42 were produced by Alkett from March 1943 to 1945, the initial 12 vehicles were built on repaired StuG III Ausf. F and F/8 from autumn 1942 to January 1943.In 1943, 10 StuG IIIs were converted to the StuG III (Flamm) configuration by replacing the main gun with a Schwade flamethrower. These chassis were all refurbished at the depot level and were a variety of pre-Ausf. F models. There are no reports to indicate that any of these were used in combat and all were returned to Ausf. G standard at depot level by 1944.In late 1941, the StuG III chassis was selected to carry the 15CM sIG 33 heavy infantry gun. These vehicles were known as Sturm-InfanteriegeschUtz 33B. Twenty-four were rebuilt on older StuG III chassis of which twelve vehicles saw combat in the Battle of Stalingrad, where they were destroyed or captured. The remaining 12 vehicles were assigned to

23RD Panzer Division.Due to the dwindling supply of rubber, rubber saving road wheels were tested during

8-14 November 1942, but did not see production.Bombing raids on the Alkett factory resulted in significant drops in StuG III production in November 1943. To make up for this loss of production, Krupp displayed a substitution StuG on a Panzer IV chassis to Hitler on 16-17 December 1943. From January 1944, the StuG IV, based on the Panzer IV chassis and with a slightly modified StuG III superstructure, entered production.Field modifications were made to increase the vehicle's survivability, resulting in diversity to already numerous variants: cement plastered on front superstructure, older Ausf.C/D retrofitted with a KwK 40 L/48 gun, Ausf.G mounting Panzer IV cupola, a coaxial MG34 through a hole drilled on a boxy mantlet.The Soviet SU-76i self-propelled gun was based on captured StuG III and Panzer III vehicles. In total, Factory #37 in Sverdlovsk manufactured 181 SU-76i plus 20 commander SU-76i for Red Army service by adding an enclosed superstructure and the 76.2MM S-1 tank gun.Approximately 10,000 StuG IIIs of various types were produced from 1940 to 1945 by Alkett (≈7,500) and from 1943 to 1945 by MIAG (2,586). From April to July 173 older Panzer III were converted to StuG III Ausf. G standard. The apx. 1299 StuH 42 and the 12 conversions from StuG III were solely built by Alkett.

|